Our business

Designing buffing compounds and discs to serve every polisher

Historical origin

Since ancient times, the mirror aspect has fascinated man.

The offensive and defensive weapons of the Greeks and Trojans were already remarkable for their brilliant polish.

For a long time, polishing was only done on armor, then on goldsmith’s objects.

The workers who did this work were called fourbisseurs.

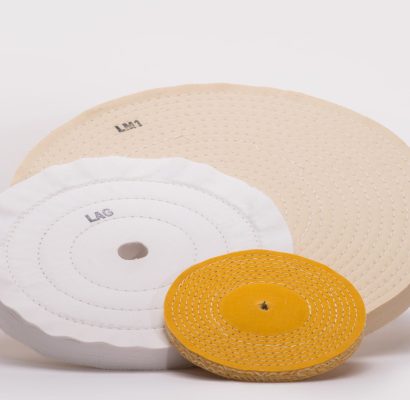

our job : To be at the service of each polisher

The principle of polishing

The practice of polishing is to refine the surface of a piece of any material (metal, plastic, wood …) to obtain a beautiful appearance, a finish or a high quality surface. This surface quality is characterized by the roughness, the shine, the brightness…

The piece to be polished is presented on the edge of a rotating disc. The disc, made of cotton, sisal or other fiber, is coated with abrasive polishing compound. This process is manual or automated.

The objective is to obtain a mirror polished aspect, also called black polish, a visual appreciation of the shine of the piece, in accordance with the aesthetic standards of the technical and luxury industries.

Several polishing steps are necessary to obtain the mirror polish: pre-polishing, polishing and finishing.